Lallemand is a global leader in the development, production and marketing of yeast, bacteria and specialty ingredients.

Dry yeast must be stored dry and below 10˚C (50˚F). For a few of the Lallemand Brewing yeasts storage under 4˚C (39˚F) is recommended; this will be indicated on packaging and also in the Technical Data Sheets. The dry yeast is packaged under vacuum. Do not use a pack of yeast that appears to have lost its vacuum, resulting in a package that is soft and easily crushed. Both humidity and oxygen will impact on the quality of the yeast and once a pack or sachet is open the yeast will deteriorate quickly. If kept sealed and stored under appropriate conditions, dry yeast can be used up to the expiration date mentioned on the package. Once a pack is open it is recommended to use the yeast as quickly as possible.

Click here for a poster with a guide to help you select the right yeast.

Sort by:

LalBrew Farmhouse™ is a non-diastatic hybrid that has been selected to make saison-style and farmhouse style beers. This product is the result of the research and development work of Renaissance Yeast in Vancouver BC, Canada. LalBrew Farmhouse™ was selected using the most advanced breeding techniques. The Renaissance research team used classical and non-GMO methods to remove the STA1 gene, responsible for the diastatic activity of Saison yeasts. Care was taken to retain normal brewing sugar utilisation to produce dry saisons. Additionally, the patented technology from University of California Davis (USA) ensures that the strain will not produce sulphurous favours, therefore enhancing the saison yeast aroma characteristics.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

BRY-97 is an American West Coast-style ale yeast that was selected from the Siebel Institute Culture Collection for its ability to deliver high quality ales. BRY-97 is a neutral strain with a high flocculation ability that can be used to make a wide variety of American-style beers.

Traditional ales made with BRY-97 include but are certainly not limited to Cream Ale, American Wheat, Scotch Ale, American Pale Ale, American Amber, American Brown, American IPA, American Stout, Russian Imperial Stout, Imperial IPA, Roggen/Rye, Old Ale and American Barleywine.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

Abbaye is an Ale yeast of Belgian origin. Selected for its ability to ferment Belgian style beers ranging from low to high alcohol, Abbaye produces the spiciness and fruitiness typical of Belgian and Trappist style ales. When fermented at higher temperatures, typical flavours and aromas include tropical, spicy and banana. At lower temperatures Abbaye produces darker fruit aromas and flavours of raisin, date and fig. Traditional styles brewed with this yeast include but are not limited to Belgian White, Belgian Blonde, Belgian Golden, Dubbel, Tripel, and Quad.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

Diamond Lager yeast is a true lager strain originating in Germany. Chosen for its robust character, Diamond Lager yeast delivers excellent fermentation performance, and has the ability to produce clean, authentic lagers. Traditional styles brewed with the Diamond include but are not limited to Munich Helles, Dortmunder Export, German Pilsner, Bohemian Pilsner, American Pilsner, Vienna Lager, Oktoberfest/Märzen, Dark American Lager, Munich Dunkel, Schwarzbier, Traditional Bock, Doppelbock, Eisbock and California Common.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

LalBrew Köln® is ideal for brewing traditional Kölsch-style beers and other neutral ales. The neutral character of this strain accentuates delicate hop aromas while imparting subtle fruity esters. Through expression of a beta-glucosidase enzyme LalBrew® Köln can promote hop biotransformation and accentuate hop flavour and aroma. Colder fermentations will be more neutral in character, while warmer fermentations will have more fruit-forward ester profile.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

LalBrew Wit™ yeast is a relatively neutral strain which can be used to produce a wide variety of wheat beer styles. Ester and phenol production is lower than for traditional hefeweizen strains such as Munich Classic. LalBrew Wit™ provides a baseline profile of banana and spice aromas, but leaves space for the brewer to showcase other spice additions typical of Belgian style beers. Traditional styles brewed with this yeast include but are not limited to Belgian Witbier, American Wheat, Berliner Weiss, Gose, Hefeweizen, Dunkelweis, and Weizenbock .

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

LalBrew® New England is an ale strain selected specifically for its ability to produce a unique fruit forward ester profile desired in East Coast styles of beer. A typical fermentation with LalBrew® New England will produce tropical and fruity esters, notably stone fruits like peach. Through expression of a β-glucosidase enzyme, LalBrew® New England can promote hop biotransformation and accentuate hop flavour and aroma. LalBrew® New England exhibits medium to high attenuation with medium flocculation, making it a perfect choice for East Coast style ales.

Click here to download the technical data sheet.

Click here to download the Lallemand Brewing Biotransformation Info Sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

Nottingham is an English style ale yeast selected for its high performance ability and versatility. Traditional styles brewed with this yeast include but are not limited to Pale Ales, Ambers, Porters, Stouts and Barleywines. Furthermore, this highly versatile yeast strain allows for tremendous creativity when brewing beers out of the regular spectrum: in addition to these traditional styles, Nottingham gives the possibility of creating styles such as Golden Ale, Kölsch, Lager-style beers, IPA, and Imperial Stout, among many others.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

LalBrew NovaLager™ is a true bottom-fermenting Saccharomyces pastorianus hybrid from the novel Group III lineage that has been selected to produce clean lager beers with distinct flavour characteristics and superior fermentation performance.

LalBrew NovaLager™ is a robust lager strain with ideal characteristics for lager beer production including fast fermentations and high attenuation. The distinct flavour profile is very clean with slight esters over a wide temperature range.

This strain is a low VDK/diacetyl producer and utilises patented technology from the University of California Davis (USA) that inhibits the production of hydrogen sulphide (H2S) off-flavours, therefore reducing the maturation time associated with lager beer production.

Through expression of a β-glucosidase enzyme, LalBrew NovaLager can also promote hop biotransformation and accentuate hop flavour and aroma making it an ideal candidate for hoppy lagers.

Brewing Properties

In Lallemand’s Standard Conditions Wort at 12°C (53.6°F) LalBrew NovaLager™ yeast exhibits: Vigorous fermentation that can be completed in 6 days.

High Attenuation and Medium Flocculation.

Aroma and flavour are clean with low to medium esters, no sulphur. This strain is POF negative.

The optimal temperature range for LalBrew NovaLager™ yeast when producing traditional styles is 10 – 20°C (50 – 68°F).

Lag phase, total fermentation time, attenuation and flavour are dependent on pitch rate, yeast handling, fermentation temperature and nutritional quality of the wort.

Click here to download the technical data sheet.

Click here to download Lallemand's Lager Strain Best Practices

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

This product is the result of the research and development work of Renaissance Bioscience Corp. (Vancouver BC, Canada) in partnership with Lallemand Brewing. LalBrew NovaLager™ was selected using classical and non-GMO breeding methods to obtain a novel Saccharomyces cerevisiae x Saccharomyces eubayanus hybrid strain that defines a novel Group III (Renaissance) lager lineage that is distinct from any other traditional Saccharomyces pastorianus strains.

LalBrew Pomona™ is a hybrid yeast that was selected for flavour and fermentation performance in hoppy beers. Named after the goddess of fruit trees, LalBrew Pomona™ produces a unique and juicy flavour profile with notes of peach, citrus, and tropical fruits. This strain was developed by our partner Escarpment Laboratories (Canada) using advanced yeast breeding and adaptive laboratory evolution in high ABV and highly hopped IPA fermentations. The result is a fruity, stress-tolerant, and robust strain that enhances biotransformation and haze for modern IPA styles.

Quick facts

| Strain | Saccharomyces cerevisiae |

|---|---|

| Beer styles | American Amber Ale, American Barleywine, American Brown Ale, American IPA, American Pale Ale, American Wheat, Berliner Weiss, Blonde Ale, Cream Ale, Dry Stout, Gose, Imperial IPA, Kettle Sours, New England IPA, New England Pale Ale, Robust Porter, Russian Imperial Stout, Session IPA |

| Attenuation | 75-84% |

| Temperature range | 18 - 22°C (64 - 72°F) |

| Flocculation | Medium |

| Aroma | Peach, Citrus, Tropical Fruit |

| Alcohol tolerance | 10% ABV |

| Pitching rate | 50 - 100g/hL |

Benefits

Why is LalBrew Pomona™ a game-changer?

Great all-around IPA strain with peach, citrus, and tropical fruit notes plus a stable haze.

- High biotransformation potential

- Unique flavour profile with notes of peach, citrus, and tropical fruits

- Selected for fermentation in high-gravity and highly hopped wort

- Haze-positive for stable haze

- Robust and repitchable

Brewing Properties

In Lallemand’s Standard Conditions 12°P Wort at 20°C (68°F), LalBrew Pomona™ yeast exhibits:

- Vigorous fermentation that can be completed in 4-5 days.

- Medium to high attenuation and medium and flocculation.

- Aromas of peach, citrus, and tropical fruits

- This strain is POF negative

- Optimal temperature range of 18-22°C (64 - 72°F)

- Lag phase, total fermentation time, attenuation and flavour are dependent on pitch rate, yeast handling, fermentation temperature and nutritional quality of the wort.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

LalBrew® Verdant IPA was specially selected in collaboration with Verdant Brewing Co. (UK) for its ability to produce a variety of hop-forward and malty beers. Prominent notes of apricot and undertones of tropical fruit and citrus merge seamlessly with hop aromas. With medium-high attenuation, LalBrew® Verdant IPA leaves a soft and balanced malt profile with slightly more body than a typical American IPA yeast strain. This highly versatile strain is well suited for a variety of beer styles including NEIPA, English IPA, American Pale, English Bitter, Sweet Stout and Sours.

Expect a large krausen.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

Kveik is a Norwegian word meaning yeast. In the Norwegian farmhouse tradition, kveik was preserved by drying and passed from generation to generation. Kveik is the original, traditional dried yeast!

The LalBrew® Voss strain was obtained from Sigmund Gjernes (Voss, Norway), who has maintained this culture using traditional methods since the 1980s and generously shared it with the wider brewing community.

LalBrew® Voss supports a wide range of fermentation temperatures between 25-40°C (77-104°F) with a very high optimal range of 35-40°C (95-104°F). Very fast fermentations are achieved within the optimal temperature range with full attenuation typically achieved within 2-3 days. The flavour profile is consistent across the entire temperature range: neutral with subtle fruity notes of orange and citrus. Flocculation is very high producing clear beers without filtration or use of process aids.

Click here to download the technical data sheet.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

Philly Sour produces moderate amounts of lactic acid in addition to ethanol in one simple fermentation step. This first yeast in the WildBrew™ series is a great choice for innovative, sessionable sour beers with refreshing acidity and notes of stone fruit. With high attenuation, high flocculation and good head retention, WildBrew™ Philly Sour is an ideal yeast for traditional styles such as Berliner Weiss, Gose, American Lambic Style, American Wild Ales and its resistance to hops make it perfect for Sour IPA’s.

Brewing Properties

In Lallemand’s Standard Conditions Wort at 20°C (68°F) WildBrew™ Philly Sour yeast exhibits:

- Fermentation that can be completed in 10 days.

- High attenuation and High flocculation. Aroma and flavour is sour, red apple and stone fruit, notably peach.

- The optimal temperature range for WildBrew™ Philly Sour yeast when producing traditional styles is 20°C(68°F) to 25°C(77°F).

- In the Lallemand standard conditions wort, typical pH of 3.2-3.5 and titratable acidity of 0.1-0.4% lactic acid are achieved. Higher lactic acid levels will be achieved in worts that are higher in glucose.

Lag phase, total fermentation time, attenuation and flavour are dependent on pitch rate, yeast handling, fermentation temperature and nutritional quality of the wort.

Please note: Philly Sour should not be used as the fermenting strain during bottle conditioning. A dedicated bottle conditioning strain should be used when bottle conditioning WildBrew™ Philly Sour fermentations.

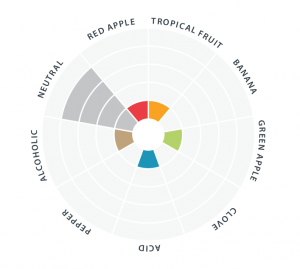

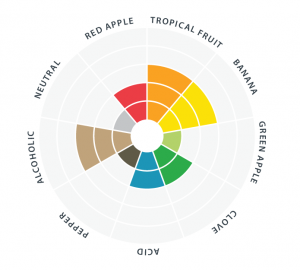

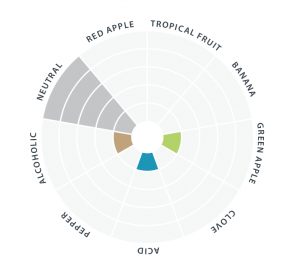

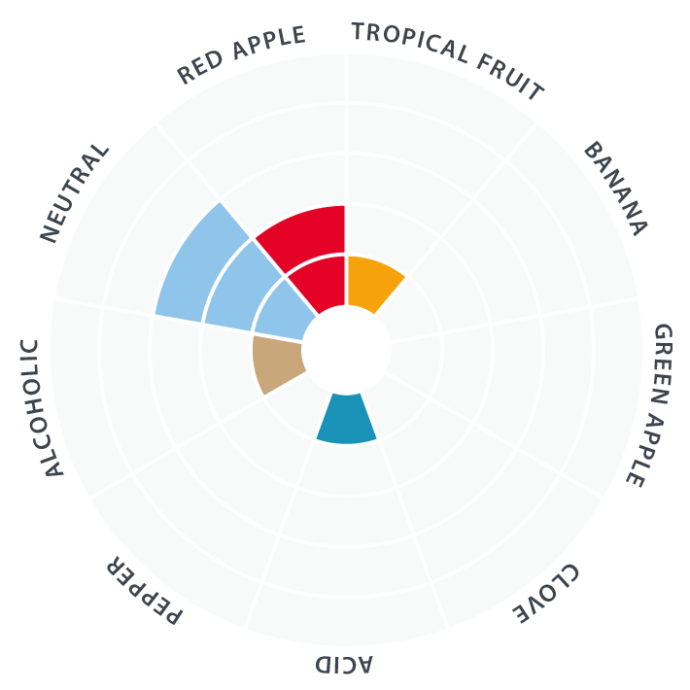

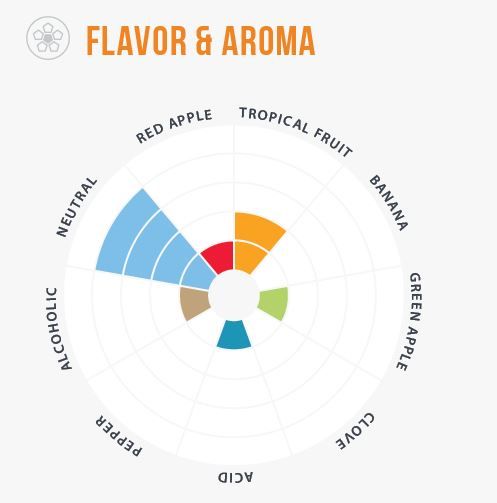

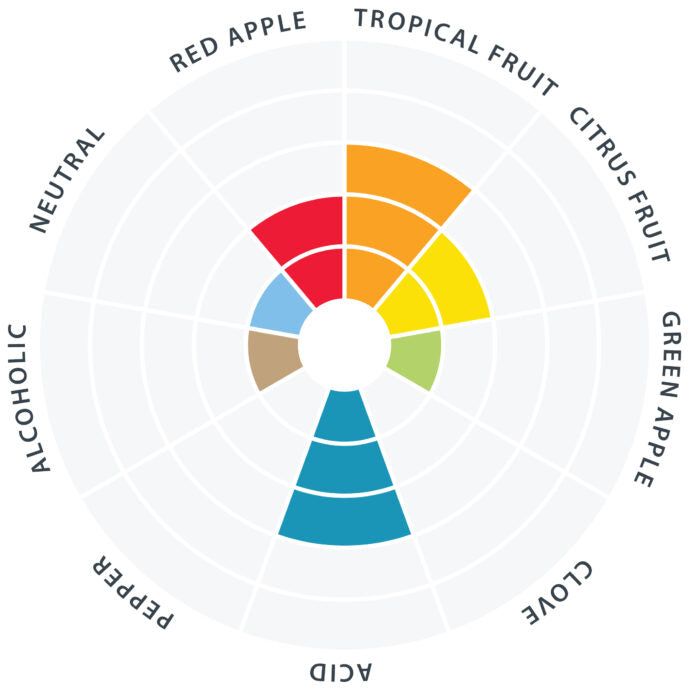

Flavour and Aroma

Click here to download the technical data sheet.

Click here for the FAQ.

Click here for the Lallemand Pitch Rate Calculator to calculate the amount of yeast you need.

Windsor ale yeast is a true English strain that produces a beer which is estery to both palate and nose with a slight fresh yeasty flavour. Beers created with Windsor are usually described as full-bodied, fruity English ales. Brewers choose Windsor to produce beers that range from pale ale to porter with moderate alcohol levels and the flavour and aroma characteristics of the best traditional ales. Traditional styles brewed with this yeast include but are not limited to Milds, Bitters, Irish Reds, English Brown ales, porters and Sweet Stouts.

Click here to download the technical data sheet.