Sort by:

NZ Made PBW Alternative

Alkaline powder, cleaner and sanitiser

CLARK PROCESS CS is a specially formulated alkaline powder cleaner and sanitiser primarily designed for pipelines and associated equipment in food manufacturing, brewing, and wine industries. It is non caustic and contains active oxygen ingredients to safely and effectively remove protein soils.

Directions for use

Use at a rate of 10g - 20g per litre of hot water.

Pump or circulate through lines to be cleaned for at least 10 minutes and then drain. Rinse well with cold water and drain. Safe for use on all metals and plastics, however spot testing is recommended.

Net contents: 2kg

Made in New Zealand.

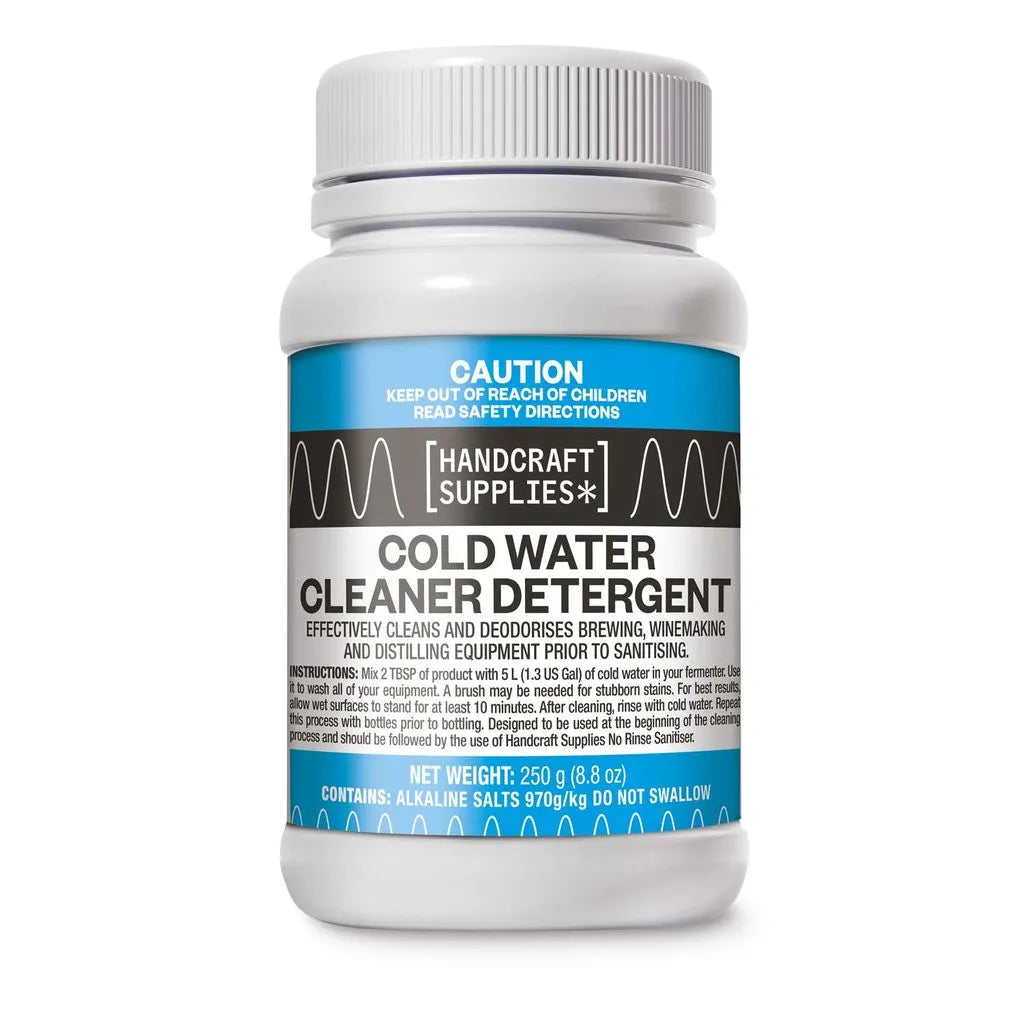

Mangrove Jack's ECD Cold Water Detergent effectively cleans and deodorises everything you use for brewing, winemaking and distilling. Cold Water ECD Cleaner Detergent is a powerful cleaner removing dirt, stains and undesirable micro-organisms, restoring your surface to its original condition.

Cleaning plays an essential role in good brewing, wine making, and distilling. You should always clean your equipment prior to sterialising.

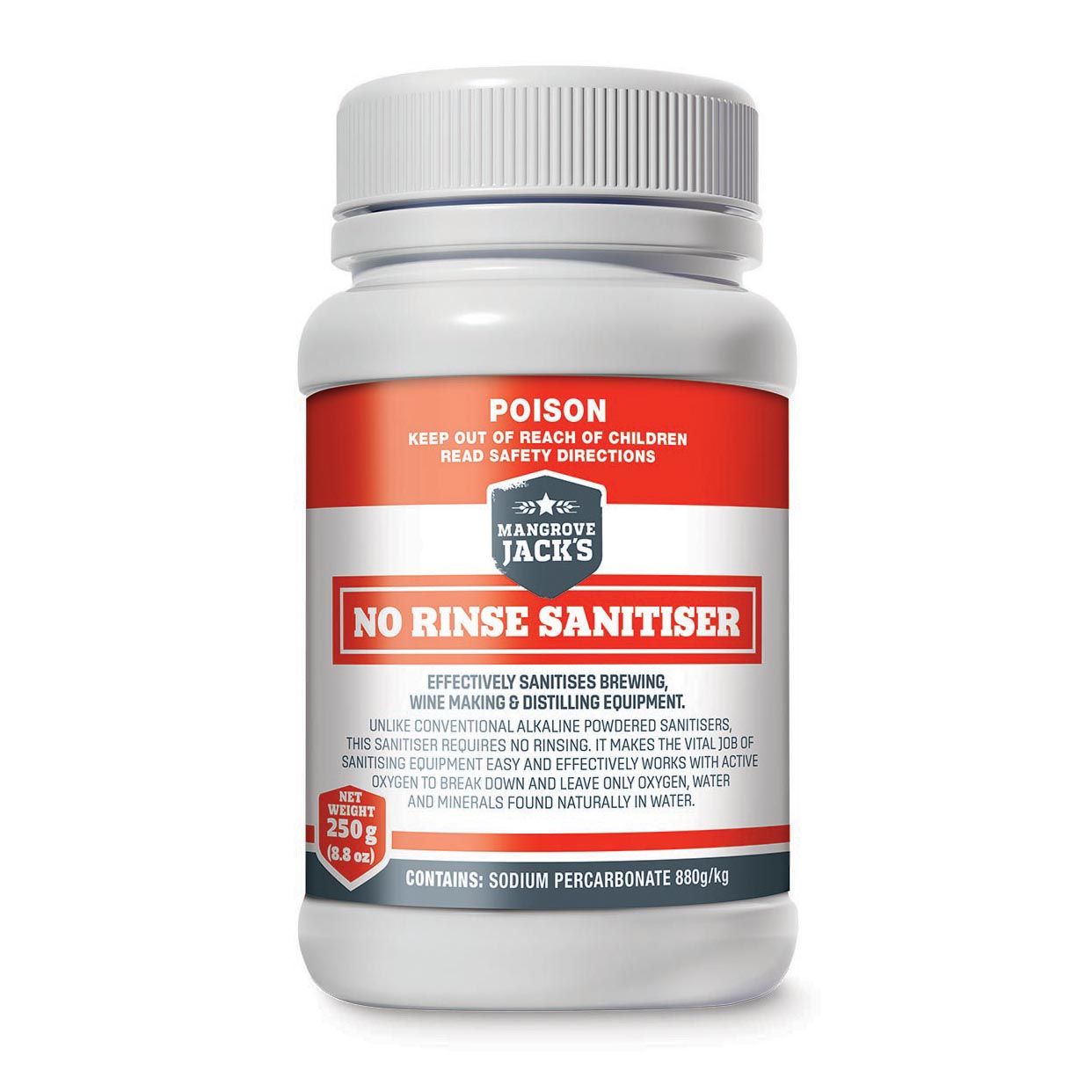

Mangrove Jack's No Rinse Sanitiser effectively sanitises brewing, wine making, and distilling equipment.

Unlike conventional alkaline powdered sanitisers, Mangrove Jack's No Rinse Sanitiser requires no rinsing. It makes the vital job of sanitising equipment easy and effective. It utilises active oxygen, which breaks down to leave only oxygen, water, and minerals found naturally in water.

Contains: Sodium Percarbonate 880g/kg

This part is only suitable for the 1L Power Sprayer (Rechargeable USB Type-C). It is not a standard thread size. It has been custom made for this product and this product only.

Includes:

Custom Thread Type Multi-Post

From: Kegland

PBW is an alkaline, non-caustic, environmentally and user friendly cleaner. This is the powder product - we also have the liquid and tablet form.

PBW is a buffered alkaline detergent that has been proven to be more than an effective substitute for caustic soda cleaners. Because of its unique formulation of buffers and mild alkalis, it is safe on skin as well as soft metals such as stainless steel, aluminium, and on plastics. PBW uses active oxygen to penetrate carbon or protein soils and is not effected by hard water.

PBW has been formulated as a clean in place (CIP) cleaner and is very effective in removing protein soils found on brew kettles, fermenters, conditioning tanks, filters and all packaging areas. The concentrations to remove these soils are typically in the 1% range. However, due to soil and water conditions this concentration will vary. To help in hard water areas PBW has been formulated with enough chelators to tolerate hard water over 17 grains (approx. 291mg calcium carbonate per litre).

PBW is an excellent choice as a soak cleaner because it does not require excessive heat as do most caustic based cleaners. This product has cleaned brass and copper filters, and industrial aluminium surfaces successfully.

Benefits

- Replaces Caustic Soda cleaners

- Effective at All Temperatures

- Free Rinsing

- Safe on Polycarbonate surfaces

- Safe to handle

- Generates 4 - 5% Oxygen

- Non-hazardous & Non-corrosive

- Excellent hard water tolerance

- Removes protein soil and staining, baked on carbon, and fatty acids

GENERAL USE DIRECTIONS

CIRCULATION CLEANING: Use 1 to 3 ounces per gallon depending on soil load. This converts to approximately 6.15gm to 22.50gm per litre. Heat to 130°F (54.5℃) to 180°F (82℃) for 30 minutes.

CARBON REMOVAL: Use 6 to 8 ounces per gallon of water. This converts to approximately 45gm to 60gm per litre. Heat to 140°F (60℃) for 4 hours or allow to soak cold overnight.

When using PBW in food processing areas the equipment that has been cleaned must be rinsed with potable water and sanitised prior to use.

PBW is an alkaline, non-caustic, environmentally and user friendly cleaner. This is the liquid product - we also have the dry powder and tablet form.

PBW is a buffered alkaline detergent that has been proven to be more than an effective substitute for caustic soda cleaners. Because of its unique formulation of buffers and mild alkalis, it is safe on skin as well as soft metals such as stainless steel, aluminium, and on plastics. P.B.W. uses active oxygen to penetrate carbon or protein soils and is not effected by hard water.

PBW has been formulated as a C.I.P. cleaner and is very effective in removing protein soils found on brew kettles, fermenters, conditioning tanks, filters and all packaging areas. The concentrations to remove these soils are typically in the 1% range. However, due to soil and water conditions this concentration will vary. To help in hard water areas PBW has been formulated with enough chelators to tolerate hard water over 17 grains.

PBW is an excellent choice as a soak cleaner because it does not require excessive heat as do most caustic based cleaners. This product has cleaned brass and copper filters, and industrial aluminium surfaces successfully.

Benefits

- Replaces Caustic Soda cleaners

- Effective at All Temperatures

- Free Rinsing

- Safe on Polycarbonate surfaces

- Safe to handle - Generates 4

- 5% Oxygen

- Non-hazardous & Non-corrosive

- Excellent hard water tolerance

- Removes protein soil and staining, baked on carbon, and fatty acids

Liquid PBW Highlights:

- Mixes into solution even at lower water temperatures

- Removes tough stains and soils with less scrubbing

- Quickly mixes into solution

- Can be used for a wide range of applications, but is especially effective with canning lines and keg cleaners

- 1-2 oz. (30-60ml) per gallon of water

Manufacturer: Five Star Chemicals

Country: USA

Powdered Brewery Wash is an alkaline, non-caustic, environmentally and user friendly cleaner. This is the tablet product - we also have the dry powder and liquid form.

PBW is a buffered alkaline detergent that has been proven to be more than an effective substitute for caustic soda cleaners. Because of its unique formulation of buffers and mild alkalis, it is safe on skin as well as soft metals such as stainless steel, aluminium, and on plastics. P.B.W. uses active oxygen to penetrate carbon or protein soils and is not effected by hard water.

PBW has been formulated as a C.I.P. cleaner and is very effective in removing protein soils found on brew kettles, fermenters, conditioning tanks, filters and all packaging areas. The concentrations to remove these soils are typically in the 1% range. However, due to soil and water conditions this concentration will vary. To help in hard water areas PBW has been formulated with enough chelators to tolerate hard water over 17 grains.

PBW is an excellent choice as a soak cleaner because it does not require excessive heat as do most caustic based cleaners. This product has cleaned brass and copper filters, and industrial aluminium surfaces successfully.

Benefits

- Replaces Caustic Soda cleaners

- Effective at All Temperatures

- Free Rinsing

- Safe on Polycarbonate surfaces

- Safe to handle - Generates 4

- 5% Oxygen

- Non-hazardous & Non-corrosive

- Excellent hard water tolerance

- Removes protein soil and staining, baked on carbon, and fatty acids

Tablet PBW Highlights

- Easy Dosing - 1 tablet for every 32 oz (approx. 1 litre) of water for 2.5 g cleaning tablet, or 1 tablet for every gallon (approx. 4 litres) of water for 10g cleaning tablets

- Removes Stubborn Stains - Tackle organic materials and stains with this non-caustic, alkaline based cleaner

- Versatile Applications - This tablet can be used to clean all types of equipment. Great for carboys, kettles, growlers, kegs, spray bottles, and so much more

- Wide Temperature Range - Has the cleaning power to work at low and high temperatures

- Effective in Hard and Soft Water - Specifically formulated for brewing, this a robust cleaning ability is a variety of environments

Manufacturer: Five Star Chemicals

Country: USA

Perfect for spraying down brewing equipment with dissolved cleaners or sanitisers.

Ideal for coupling with Multi-Post for Power Sprayer to turn the sprayer into a pressurised line cleaning device.

Includes:

1L Reservoir Tank

Power Sprayer Nozzle and Dip Tube

White plastic adjustment head sprayer

15cm USB C to Standard USB (for charging purposes)

Food Grade

This product is made from food grade, Santoprene, PP, PE, Silicone and Stainless Components.

Battery Life

The pump has large 18650 li-ion rechargeable battery. On a full charge the battery will empty the 1L tank 18-30 times so it lasts for ages.

NOTE: If you use fine mist it will be closer to 18 times but if you use a jet/stream the battery will last closer to 30 times.

Does Not Include:

USB wall charger

Multi-Post for Power Sprayer

From: Kegland

Saniclean is a low-foaming, acid based, final rinse sanitiser.

- Effectively removes odours and flavours especially from draft lines or other dispensing products.

- Great for both CIP and manual applications.

- Not to be used on soft metals such as aluminium.

Instructions:

- Thoroughly clean surfaces with PBW or compatible cleaner.

- Mix 2 oz. (60ml) Saniclean for every 5 gal. (19L) of water. (Will be low-foaming)

- Apply on surface with cloth, mop, sponge, spray, or immersion.

- If using spray application, use a coarse mist, pump, or trigger sprayer and spray 15-20cm from surface and follow up with a brush or sponge.

- Allow for contact time of at least 2-3 minutes.

- Drain, but do not rinse.

From: Five Star Chemicals

Sodium Metabisulphite is a sulphur based compound that is used primarily to sterilise wine and cider making to kill bacteria and to inhibit the growth of most wild yeast.

It can also be used to eliminate both free chlorine and the more stable form, chloramine, from water.

One gram of metabisulphite will impart approximately 60 parts-per-million of sulphur dioxide (SO2) to each litre of wine.

As a guide, to sanitise wine must add 0.2 g of metabisulphite per litre of juice. Pre-dissolve it in a small quantity of water before adding to the must. Allow the must to ventilate in an open container for 24 hours before adding yeast.

Here is a link to an excellent article on the use of metabisulphate.

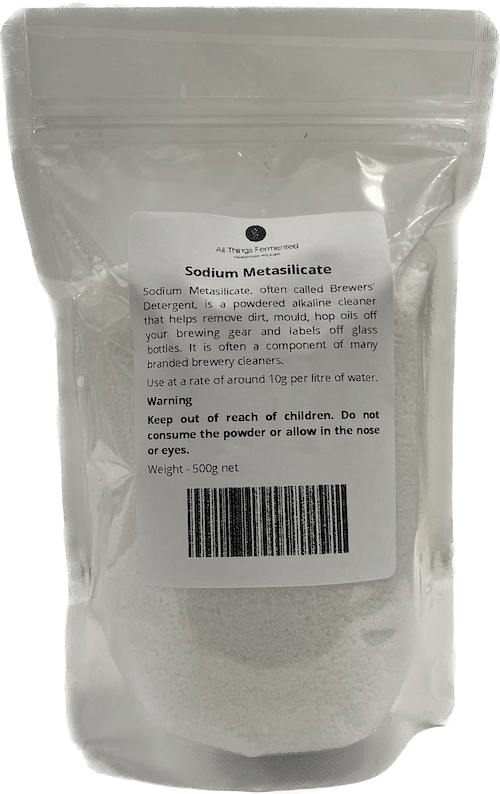

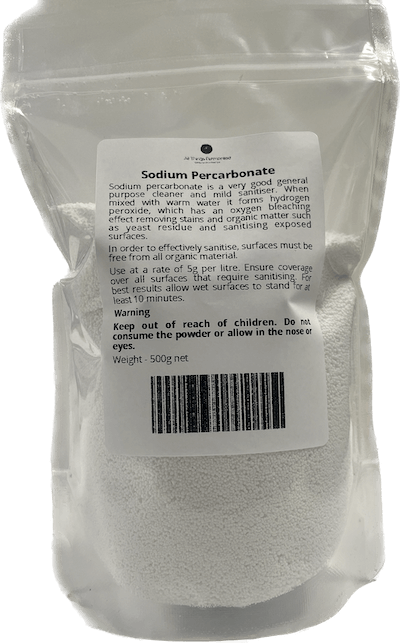

Sodium percarbonate is a very good general purpose cleaner and mild sanitiser. When mixed with warm water it forms hydrogen peroxide, which has an oxygen bleaching effect removing stains and organic matter such as yeast residue and sanitising exposed surfaces.

Over time, sodium percarbonate breaks down into oxygen and water, so there is no need to rinse the product. In order to effectively sanitise, surfaces must be free from all organic material.

Use at a rate of 5g per litre. Ensure coverage over all surfaces that require sanitising. For best results allow wet surfaces to stand for at least 10 minutes.

Star San is a no rinse sanitiser made from a blend of phosphoric acid and dodecylbenzenesulfonic acid. This synergistic blend provides a unique killing system that is unaffected by excessive organic soils.

Star San is also a self-foaming sanitiser. It can be applied through a foamer to produce self-adhering sanitising foam for external sanitation. Star San is also an excellent sanitiser for hand application. Sanitising with Star San on a daily basis will leave equipment in an acid condition that will eliminate water spotting. It is not recommended to use Star San on soft metals because of the acid nature of this product.

BENEFITS

- Broad Spectrum Bactericide and Fungicide

- Not Affected by Organic Materials

- No Rinse Requirement When Used at 300 ppm

- Accepted by U.S.D.A. as a General Sanitiser in all Departments

GENERAL USE DIRECTIONS

All surfaces should be cleaned and rinsed before sanitising with Star San.

Directions: At a dilution rate of 1 ounce (29.57ml) to 5 gallons (18.93L) of water, Star San will provide 300 ppm of dodecylbenzenesulfonic acid. After 1 to 2 minutes contact time, drain sanitising solution from equipment thoroughly. Do not rinse. If using Star San in CIP, proper water balance must be maintained or your pump may cavitate. If used at a rate of more than 300 ppm, a potable rinse is required.

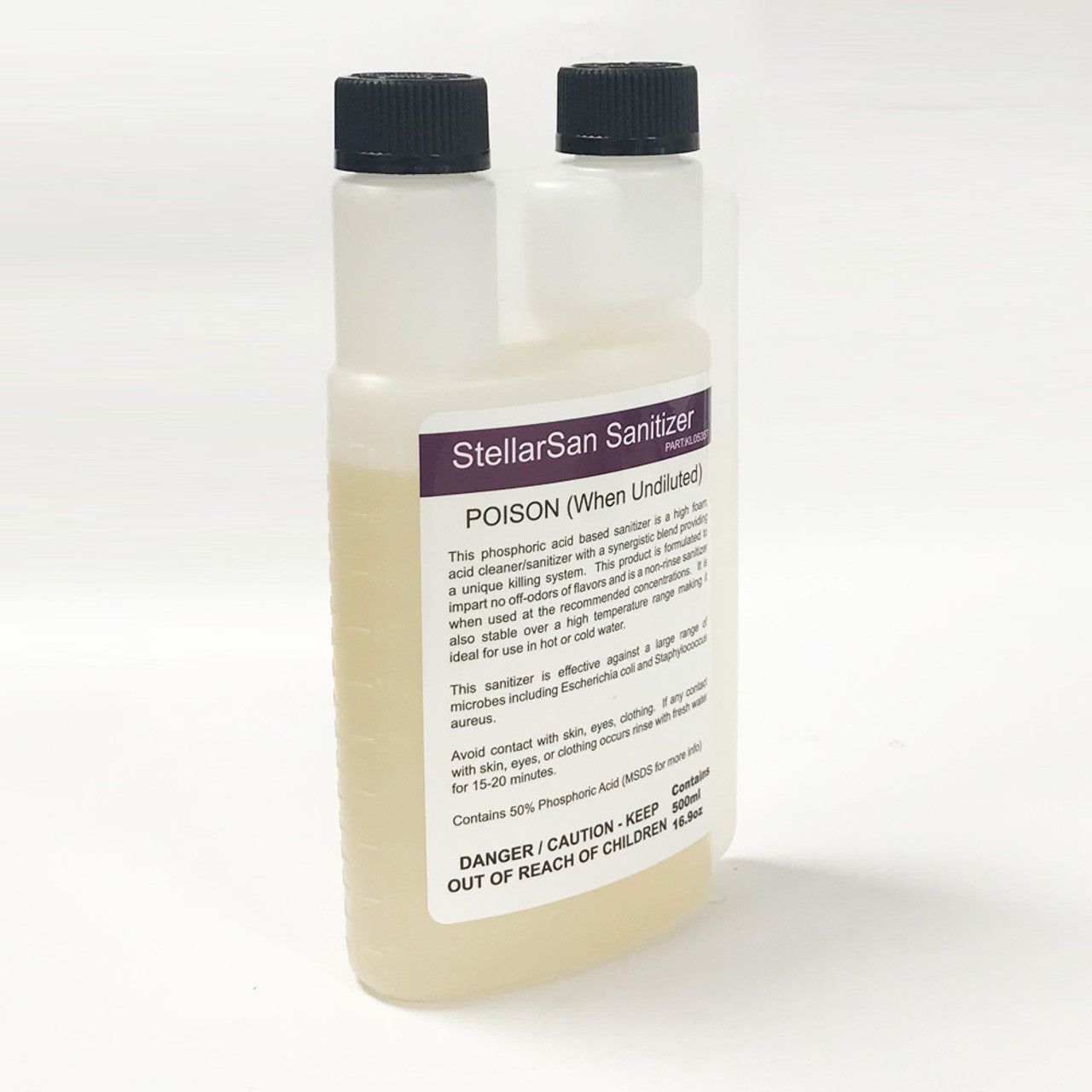

StellarSan Sanitiser 500mL - 100% Food Grade non-rinse sanitiser that can be diluted to 333L with the dual chamber mixing bottle compartment. Simply twist off the small measuring compartments lid, squeeze the bottle and it will start to fill that chamber only.

Even when you're finished sanitising your products in a bucket for example, you can still re-use the sanitiser over and over again. Making it a no brainer for your brewing sanitising needs and the cost to you is greatly reduced.

The new and improved phosphoric acid blend provides a unique microorganism killing system, unaffected by organic soils and delivering a high foaming formulation with optimum coverage and penetration. It is perfect for sanitising your brewing equipment and surface areas. Not suitable for use on wood, unglazed porcelain or other porous materials. It is also not suitable for use on soft metal such as aluminium, copper or brass.

Please note that foam is okay! Pour your wort directly onto the foam as this is a foaming non-rinse formulation. The formula can be metabolised by the yeast and will act as a nutrient assisting yeast growth. Follow this procedure and it will not impart any off-odours or flavours.

Unlike other harsh chemical sanitisers, StellarSan is non-staining, and stable over a wide range of temperatures.

Phosphoric acid, which is in this formulation, also helps keep your stainless in good condition and will improve the stainless properties.

Use at a dilution rate of 1.5ml per litre.