Sort by:

No bottling or wasting that little bit left over from standard sized 23L batches and a 19L keg and perfect for smaller experimental batches.

The 5L can be used as a growler without the ball lock cap - perfect for filling up at your favourite tap room or brewery!

- Portable size

- Pressure carbonate (using the ball lock cap)

- Stainless steel body

- Handles for easy transportation

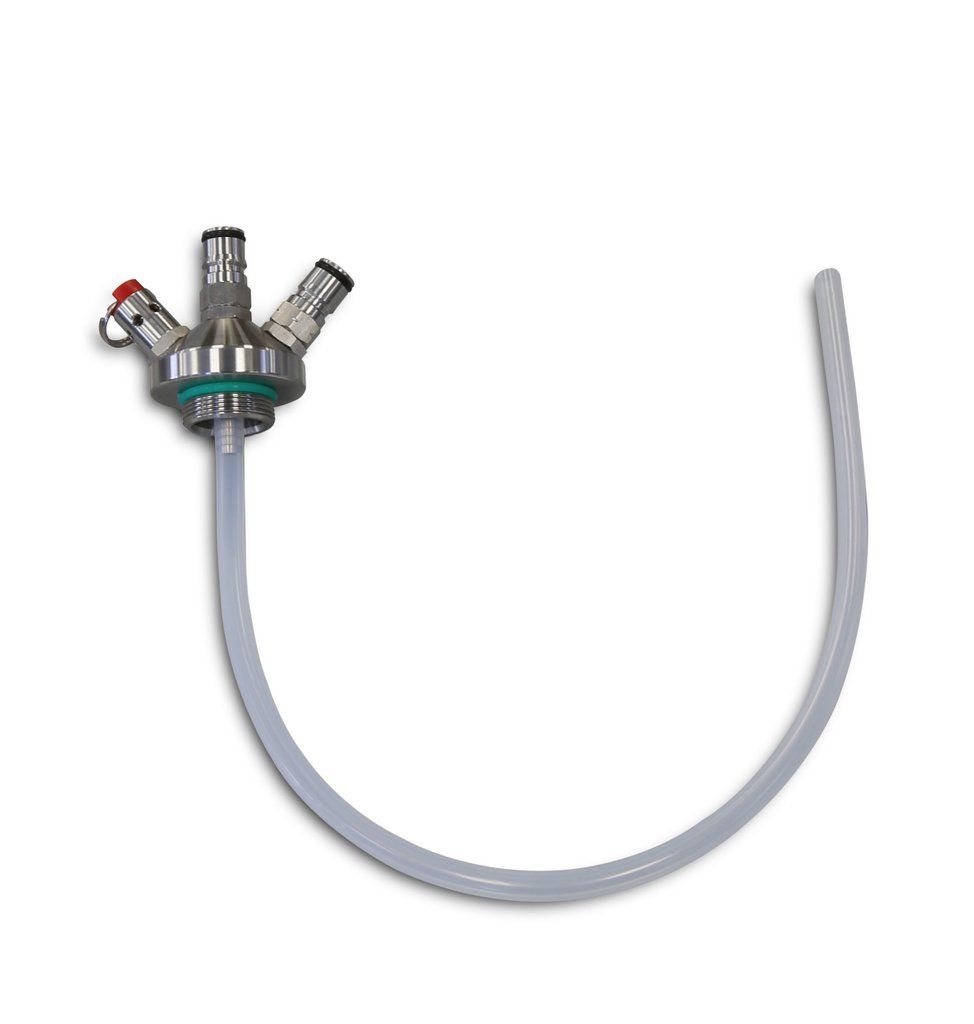

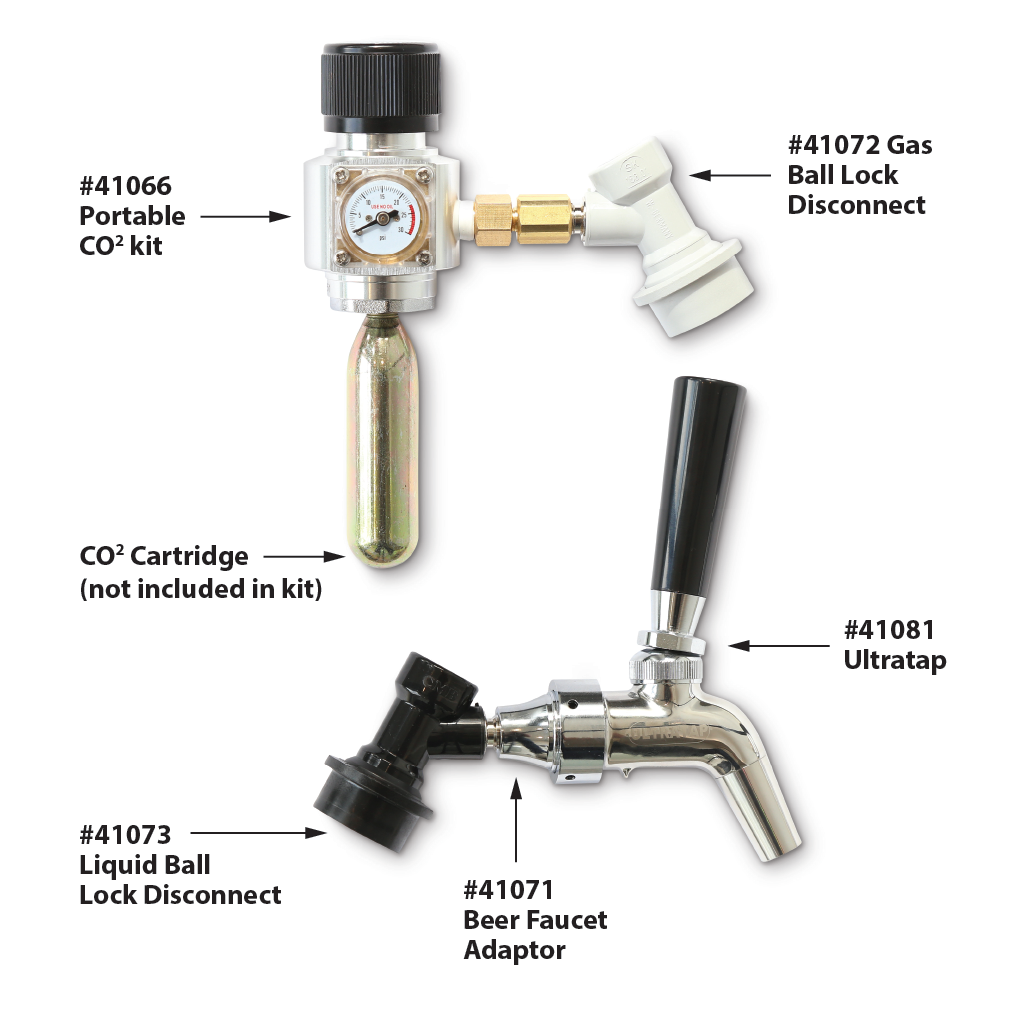

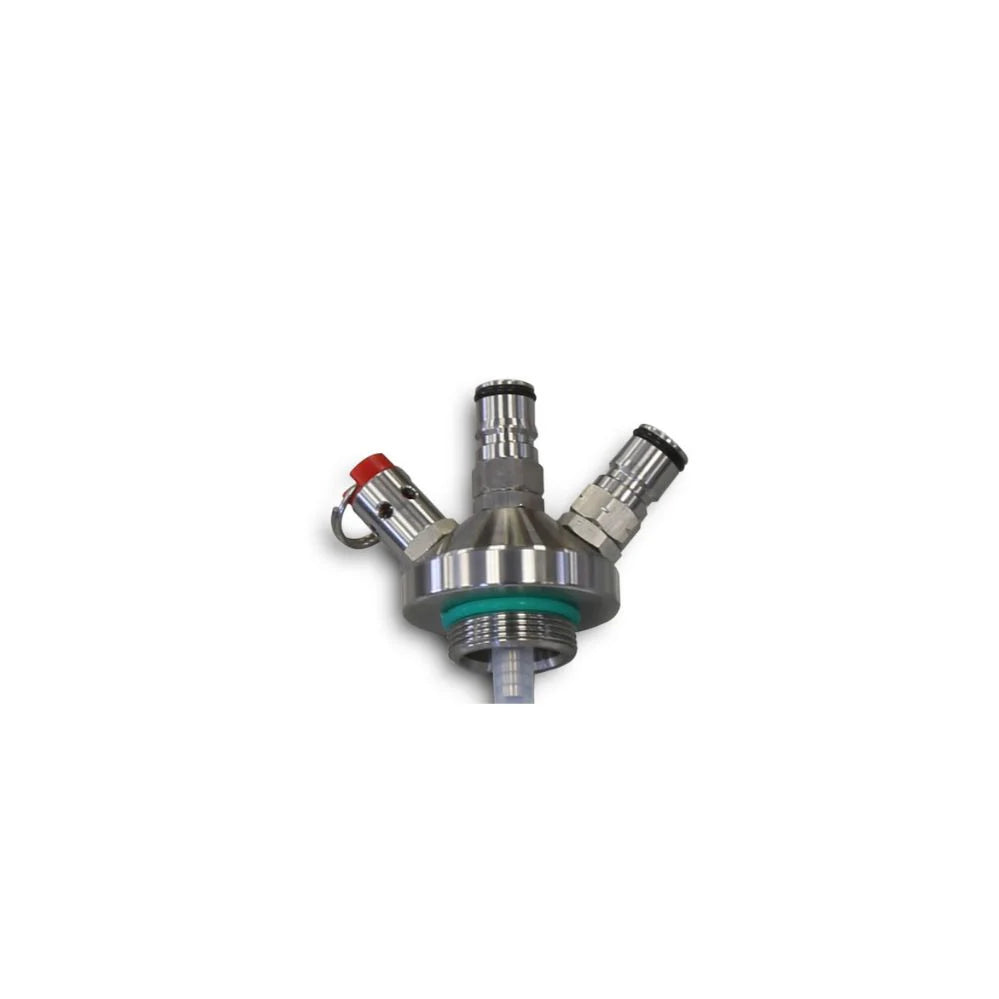

With the portable dispensing kit, you will now be able to dispense straight from the keg (think party kegs!) which means you will be able to take your homemade beer to parties, BBQs and other gatherings where you can share your brews with others.

The kit has an inlet for standard threaded disposable 16g CO2 canisters plus adaptors for paintball cylinders, 74g CO2 cartridges and SodaStream cylinders!

Kit Contains:

- Portable CO2 Kit

- Ultratap

- Beer Faucet Adapter

- Threaded Gas Ball Lock Disconnect

- Threaded Liquid Ball Lock Disconnect

Compact and versatile, the Mangrove Jacks Mini Keg delivers professional-grade carbonation in a portable 10L format.

The stainless steel construction features sturdy handles for easy transport, while the ball lock cap enables pressure carbonation for experimental batches and small-scale brews.

Note: tap not included, but compatible with standard ball lock taps, making it an ideal addition to existing kegerator setups or a standalone solution for home brewers seeking flexibility and control.

No bottling or wasting that little bit left over from standard sized 23L batches and a 19L keg and perfect for smaller experimental batches.

The 3L can be used as a growler without the ball lock cap - perfect for filling up at your favourite tap room or brewery!

- Portable size

- Pressure carbonate (using the ball lock cap)

- Stainless steel body

- Handles for easy transportation

No bottling or wasting that little bit left over from standard sized 23L batches and a 19L keg and perfect for smaller experimental batches.

The 5L can be used as a growler without the ball lock cap - perfect for filling up at your favourite tap room or brewery!

- Portable size

- Pressure carbonate (using the ball lock cap)

- Stainless steel body

- Handles for easy transportation

An MFL Check Valve to prevent back flow, with 1/4″ FFL outlet x 1/4″ MFL Inlet.

Use this check valve on ball lock gas connectors with MFL thread. Its internal mechanism prevents accidental back-flow of beer into the gas line on your kegging set up.

- Stainless steel 304

- Made for gas connectors with 1/4″ MFL threads

- Prevents liquid from entering your gas lines

- Permanent markings show flow direction

From: Krome Dispense

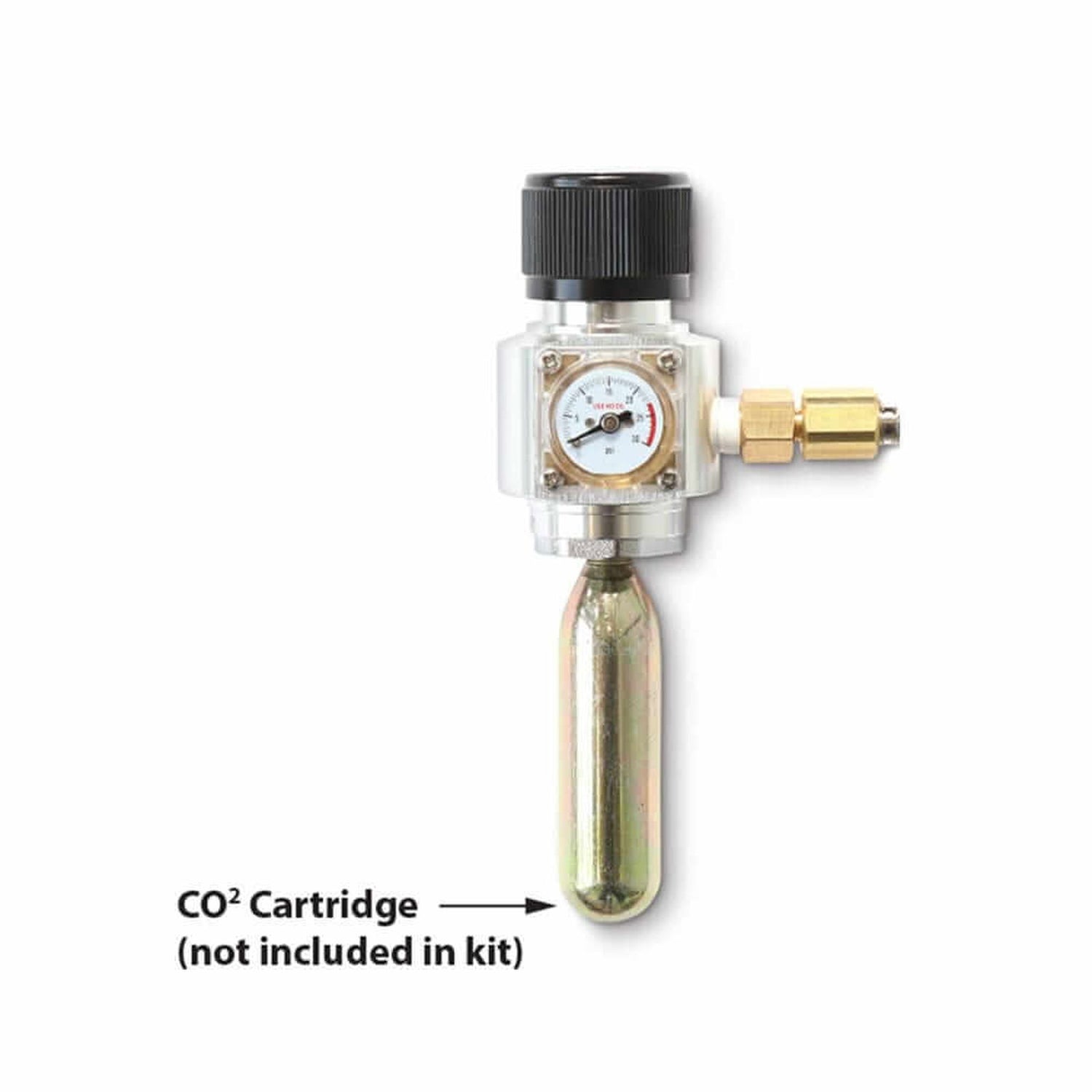

The Portable CO2 Mini Regulator Kit is the perfect regulator to use when you don't want to be carting around a large co2 cylinder. Perfect for taking kegs or mini kegs to parties or gatherings, making dispensing a perfectly carbonated beer easy.

The kit has an inlet for standard threaded disposable 16g CO2 canisters plus adaptors for paintball cylinders, 74g CO2 cartridges and SodaStream cylinders.

Whats Included

- Regulator with aluminium body

- 3 x Inlet adapters for different connections

- Outlet fitting

Mini Core 360 Adaptor for 74g Canister/Bulb (G1/2 Male x 5/8-18UNF Female).

This adaptor for the Core 360 Mini Regulator will allow you to use the oversized disposable 74gram co2 bulbs so you can take your keg system anywhere.

The oversized 74gram CO2 bulbs are large enough to dispense almost a whole 19L keg of beer so they are a really great choice for portable keg systems.

NOTE: The regulator itself and 74grams bulbs need to be purchase separately.

From: Kegland

Mini Gauge 0-15psi (0-1.5bar) - for inline Duotight regulator or Blowtie.

This gauge is designed to fit into either our inline regulator or our Blowtie unit. These can be used for water or gas.

Specifications

- Pressure: 0-15psi (0-1bar)

- Graduations: PSI + Bar

- Material: Brass/Plastic/Copper Capillary

- Gauge Diameter: 20mm

- Probe Diameter: 7.8mm (designed to fit 8mm hole)

- Accuracy: These gauges are accurate to 10% of the whole pressure range.

WARNING:

Do not exceed gauge pressure. If you exceed gauge pressure it will damage the capillary in the gauge and prevent the gauge from working correctly. NEVER exceed the maximum gauge display pressure range.

Not tested or approved for pure oxygen.

If you are looking for a compact digital gauge with backlight illumination click here.

From: Kegland

Digital Illuminated Mini Gauge 0-90psi (0-6.2bar) - Duotight 8mm Stem.

Traditional analogue gauges require a small capillary mechanism where a small pipe expands and unravels under pressure. This in turn drives a mechanical cog to rotate the gauge needle. This age old technique works quite well especially in large gauges, but as this mechanism is manufactured smaller and smaller a tradeoff between accuracy and size becomes the issue. With very small gauges, such as a 27mm x 27mm Mini Gauge, it's difficult to make them better than 10% accuracy due to the physical constraints of the mechanical components.

Kegland has developed the worlds most compact mini digital gauge with backlight illumination. This very compact design retains high accuracy while still meeting the desirable small form factor. This meets the growing need as mini keg systems, mini regulators and other more compact keg dispensing solutions is required.

Specifications:

Battery Life: More than 2 years (using the mini gauge once a day)

Battery Type: CR2032

Auto Battery Saver: YES, screen automatically turns off after 15sec

Size: 27mm x 27mm

Duotight Stem: 8mm

NOTE: This gauge is not suitable for measuring pressure of liquids. It is only for measuring gas pressure. If liquid gets into the pressure transducer it will damage the gauge. If you want to measure liquid pressure you can purchase one of these analogue gauges:

KL07696 - Duotight Compatible Push in Pressure Gauge

From: Kegland

Mini Gauge 0-90psi for Integrated Blowtie and In-line regulators - Digital Illuminated

$24.95

Unit price perMini Gauge 0-90psi for Integrated Blowtie and In-line regulators - Digital Illuminated

$24.95

Unit price per

Digital Illuminated Mini Gauge 0-90psi (0-6.2bar) for Integrated Blowtie and In-line regulators.

Traditional analogue gauges require a small capillary mechanism where a small pipe expands and unravels under pressure. This in turn drives a mechanical cog to rotate the gauge needle. This age old technique works quite well especially in large gauges but as this mechanism is manufactured smaller and smaller a tradeoff between accuracy and size becomes the issue. With very small gauges such as a 27mm x 27mm Mini Gauge it's difficult to make them better than 10% accuracy due to the physical constraints of the mechanical components.

Kegland has developed this compact mini digital gauge with backlight illumination. This very compact design retains high accuracy while still meeting the desirable small form factor. This meets the growing need as mini keg systems, mini regulators and other more compact keg dispensing solutions is required.

Specifications:

Battery Life: More than 2 years (using the mini gauge once a day)

Battery Type: CR2032

Auto Battery Saver: Yes, screen automatically turns off after 15sec

Size: 27mm x 27mm

Radial O-ring Stem: 7.8mm Bore

NOTE: This gauge is not suitable for measuring pressure of liquids. It is only for measuring gas pressure. If liquid gets into the pressure transducer it will damage the gauge. If you want to measure liquid pressure you can purchase one of these analogue gauges:

This digital mini gauge can be used to upgrade your:

Blowtie Spunding Valve

Inline Regulator

Core 360 Mini Regulator

If you would like to use the mini gauge to attach to other hobbie projects then you should consider the Duotight Compatible Digital Mini Gauge with part number KL18081 that has the 8mm duotight push in stem. This makes it easy to fit to other 8mm duotight fittings, tubing etc.

From: Kegland

An insulated, neoprene jacket for mini kegs with glow-in-the-dark Kegland branding. Great for BBQs, camping, or parties.

Features:

1. 8mm thick neoprene. Most other keg jackets are only 4mm meaning they simply do not insulate as well.

2. 16gram CO2 bulb pockets.

3. Velcro around the top so you can attach various accessories.

4. Comes with heavy duty webbing shoulder strap.

From: Kegland

This is the Dual Pressure MK4 CO2 Regulator - you'll find the single pressure regulator here.

Need to set two different CO2 pressures for different beers on tap? Then you'll need two regulators to do it properly. With this MK4 Dual Pressure Regulator you'll be able to screw it into your CO2 bottle and fire away with two different pressures. No need to removing the High Pressure gauge off one regulator, buying an attachment and joining the two together.

This new MK4 Model regulator has several advantages including:

1. Safer design with colour coded pressure release valves

2. Easy mounting option

3. Optional extras such as gauge guard

4. Better body design and more reliable

Now comes with Duotight 8mm push-fit fittings rather than barbs. We recommend using thread tape to ensure a good leak free seal between the Duotight MFL fitting and the regulator.

From: Kegland

Note: CO2 bottle not included.

This part is only suitable for the 1L Power Sprayer (Rechargeable USB Type-C). It is not a standard thread size. It has been custom made for this product and this product only.

Includes:

Custom Thread Type Multi-Post

From: Kegland

Nukatap Concave / Angle Collar - Black

This is the hard reinforced plastic piece that wedges between the beer tower font and the shank.

If you are wanting to mix up your Kegerator / Draught System with a bit of black flair, this would be a great place to start if you already have Stainless Steel Shanks and don't want to spend money on an entire shank again.

It is important to note to be gentle with these black parts as scratches will show up more clearly compared to the Stainless Steel look versions.

Note: shank not included.

From: Kegland

Black NukaTap Shank Threaded Collar Piece Only

This is the moveable piece that tightens the NukaTap to the Short / Long Shank but black in colour.

If you are wanting to mix up your Kegerator / Draught System with a bit of black flair, this would be a great place to start if you already have Stainless Steel Shanks and don't want to spend money on an entire shank again.

It is important to note to be gentle with these black parts as scratches will show up more clearly compared to the Stainless Steel look versions.

It does not come with the circlip from the Shank as it is a replacement part for aesthetic purposes.

Note: shank not included.

From: Kegland

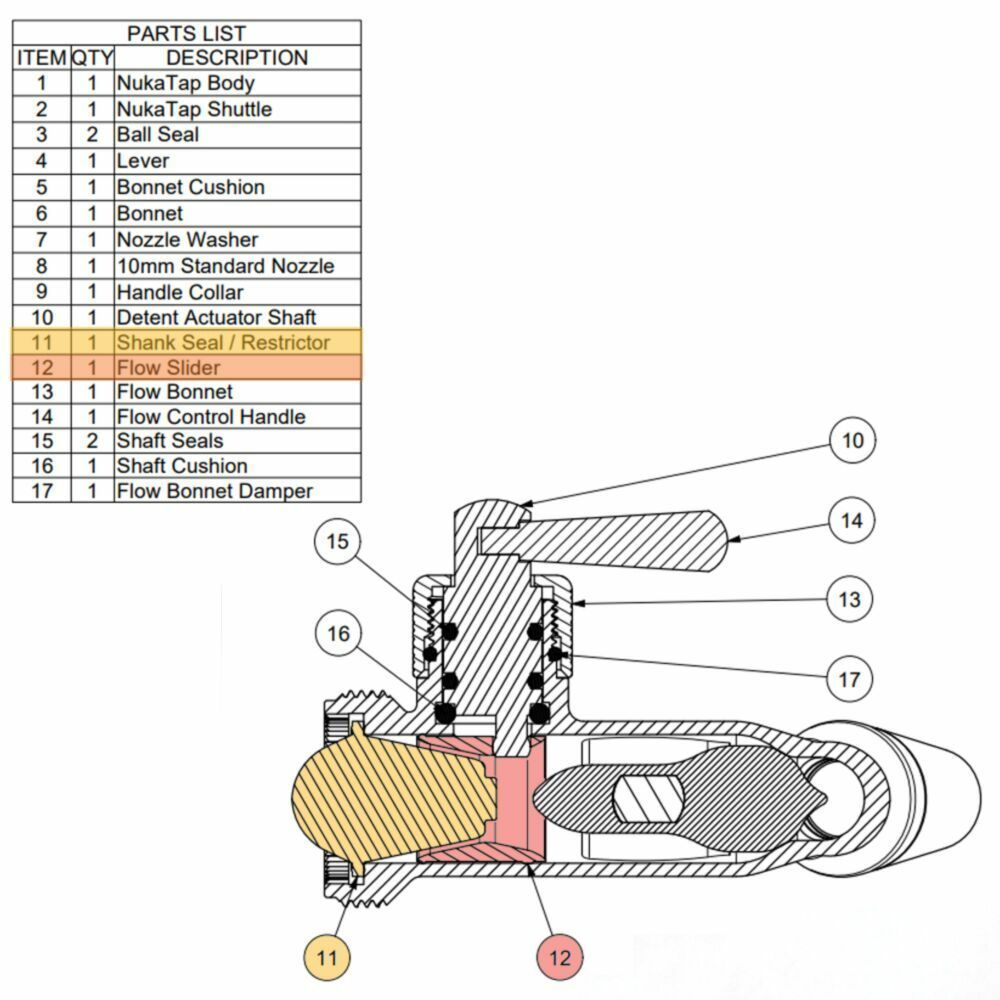

Nukatap - the latest in beer dispensing tap technology. This is the Flow Control model - looking for the non-flow control Nukatap?

What makes the Nukatap different among the other manufactured styles of taps on the market?

- First Pour Foam Reduction in Thermal Mass

- Improved Laminar Flow

- Most Sanitary Forward Sealing Design Design

- Longer Life Seals

- More Versatile Tap Handle Angle

First Pour Foam Reduction

The reduction in thermal mass significantly reduces the first pour foam effect. The tap is often the warmest part of the draft system as it protrudes from the font/tower/fridge. As a result, it acts like a heat sink and only works well once enough cold beer flows through it to cool the tap body down. This reduction of thermal mass significantly improves the foam that is poured while the tap is cooling down.

Laminar Flow

The Nukashuttle design is the world’s first seamless shuttle. After many months of modelling and testing this new "Nuke" shaped shuttle design has the most fluid dynamic shuttle shape ever manufactured for a forward sealing tap. The streamline "nuke/missile" shape is how this new innovation earned its name "Nukatap". This leap forward in laminar flow means even highly carbonated beers pour like a dream with minimal turbulence and giving you the perfect pour every time.

Most Sanitary Design

The Nukashuttle is the world’s first seamless single-piece design. Traditional taps have a seal that is seated on a stainless-steel body creating small fissures that harbour solids, are potential sites for infection, and are not as ideal for clean in place (CIP). The Nukashuttle is an advanced TPV rubber matrix that been seamlessly formed over a durable PP skeleton. This single-piece design takes away the traditional fissures found in older manufacturing methods.

Long Life Seals

Unlike many other taps that use rubbers that can be degraded with caustic and acid compounds, the Nukatap has been made to suit a wide range of conditions. It's becoming more common to see sour beers/kombucha and other acetic and lactic acid beverages dispensed using draft systems. These acids, in particular, could cause an attack on the sealing compounds resulting in downtime, loss of product and reduced maintenance intervals. The Nukatap solves this problem and is the most chemically resistant tap we have ever manufactured. Unlike some older tap styles that have "metal on metal" rubbing components that can wear over time and have a "raspy feel" the Nukatap has been manufactured with a smooth gliding action that guarantees the longevity of the tap components. The TPV rubber matrix shuttle is also one of the most durable sealing mechanisms that can tolerate large amounts of leverage force from long tap handles that would otherwise traditionally degrade the seals in other tap designs. Other forward sealing designs exist but nothing with the same level of reliability. It’s easy to find other “perl” forward sealing design taps however these taps use a floating o-ring design which by all means is equally as sanitary however the floating o-ring requires the o-ring to move within the tap body to seal correctly. This movement is typically a problem as the tap ages and/or is not serviced regularly. The Nukatap bypasses this seal as the entire Nukashuttle is a single sealing piece.

Tap Handle Angle - 2.5degree Reverse Angle

The Nukataps have been manufactured with a 2.5 degree reverse angle. This allows for a wider range of taps handles to be used, in particular, long and/or heavy handles to work perfectly irrespective of the installation conditions.

Forward Sealing Design

Just like the Intertap and its predecessors, the Nukatap shuts off the flow at the front of the tap which in turn keeps wild yeast and bacteria out of the interior of the tap body.

What does Rear Sealing Design Mean?

Typically most beer taps use a rear sealing design and the beer in the tap drains from the body of the tap with the help from a vent hole drilled at the front of the tap. This drainage hole is a dark and wet cavity and is an ideal place for airborne bacteria and wild yeast to reproduce leaving a foul film that deteriorates the quality of your beer. Every time the faucet is opened contamination can occur.

Compatible with Intertap and Nukatap accessories:

- Stout Spout

- Ball Lock Post Spout

- Growler Spout

From: Kegland

NukaTap - Flow Control Gen3 Seal Kit (Suits NukaTap FC G2)

This pretty handy kit contains all the seals needed for the NukaTap FC Gen2.

If you're still using a Gen1 FC NukaTap, this kit includes all the bits you need to upgrade the tap to the Gen2 mechanism.

The majority of these seals would never normally need to be replaced. But in the event of accidental loss / extreme commercial use, please replace said washers with the addition of food-grade lubricant to ensure their longevity.

If you have not changed your seals before, it's a great idea to take a note of which seal goes where as you remove the old ones!

Includes:

- The Nuke!

- Bonnet Washer

- 2 x Black POK Cup Seal Washers

- Nozzle Washer

- Flow Control Arm Seals

- Flow Control Arm Thread Seals

- Gen2 Flow Control Mechanism

From: Kegland

Nukatap - the latest in beer dispensing tap technology.

What makes the Nukatap different among the other manufactured styles of taps on the market?

- First Pour Foam Reduction due to reduction in Thermal Mass

- Improved Laminar Flow

- Most Sanitary Forward Sealing Design Design

- Longer Life Seals

- More Versatile Tap Handle Angle

First Pour Foam Reduction

The reduction in thermal mass significantly reduces the first pour foam effect. The tap is often the warmest part of the draft system as it protrudes from the font/tower/fridge. As a result, it acts like a heat sink and only works well once enough cold beer flows through it to cool the tap body down. This reduction of thermal mass significantly improves the foam that is poured while the tap is cooling down.

Laminar Flow

The Nukashuttle design is the world’s first seamless shuttle. After many months of modelling and testing this new "Nuke" shaped shuttle design has the most fluid dynamic shuttle shape ever manufactured for a forward sealing tap. The streamline "nuke/missile" shape is how this new innovation earned its name "Nukatap". This leap forward in laminar flow means even highly carbonated beers pour like a dream with minimal turbulence and giving you the perfect pour every time.

Most Sanitary Design

The Nukashuttle is the world’s first seamless single-piece design. Traditional taps have a seal that is seated on a stainless-steel body creating small fissures that harbour solids, are potential sites for infection, and are not as ideal for clean in place (CIP). The Nukashuttle is an advanced TPV rubber matrix that been seamlessly formed over a durable PP skeleton. This single-piece design takes away the traditional fissures found in older manufacturing methods.

Long Life Seals

Unlike many other taps that use rubbers that can be degraded with caustic and acid compounds, the Nukatap has been made to suit a wide range of conditions. It's becoming more common to see sour beers/kombucha and other acetic and lactic acid beverages dispensed using draft systems. These acids, in particular, could cause an attack on the sealing compounds resulting in downtime, loss of product and reduced maintenance intervals. The Nukatap solves this problem and is the most chemically resistant tap we have ever manufactured. Unlike some older tap styles that have "metal on metal" rubbing components that can wear over time and have a "raspy feel" the Nukatap has been manufactured with a smooth gliding action that guarantees the longevity of the tap components. The TPV rubber matrix shuttle is also one of the most durable sealing mechanisms that can tolerate large amounts of leverage force from long tap handles that would otherwise traditionally degrade the seals in other tap designs.

Other forward sealing designs exist but nothing with the same level of reliability. It’s easy to find other “perl” forward sealing design taps however these taps use a floating o-ring design which by all means is equally as sanitary however the floating o-ring requires the o-ring to move within the tap body to seal correctly. This movement is typically a problem as the tap ages and/or is not serviced regularly. The Nukatap bypasses this seal as the entire Nukashuttle is a single sealing piece.

Tap Handle Angle - 2.5 degree Reverse Angle

The Nukataps have been manufactured with a 2.5 degree reverse angle. This allows for a wider range of taps handles to be used, in particular, long and/or heavy handles to work perfectly irrespective of the installation conditions.

Forward Sealing Design

Just like the Intertap and its predecessors, the Nukatap shuts off the flow at the front of the tap which in turn keeps wild yeast and bacteria out of the interior of the tap body.

What does Rear Sealing Design Mean?

Typically most beer taps use a rear sealing design and the beer in the tap drains from the body of the tap with the help from a vent hole drilled at the front of the tap. This drainage hole is a dark and wet cavity and is an ideal place for airborne bacteria and wild yeast to reproduce leaving a foul film that deteriorates the quality of your beer. Every time the faucet is opened contamination can occur.

Compatible with Intertap and Nukatap accessories:

- Auto-Close Spring

- Stout Spout

- Ball Lock Post Spout

- Growler Spout

From: Kegland

The Growler Filler Spout extension can be used on any of the Nukatap / Intertap beer taps. The spout has a 13mm barb to which you can attach some hose so you can fill your growler from the bottom up to minimise foaming.

Simply un-screw the regular nozzle and screw on the Growler Filler Spout with hose attached and use as you would a growler filler tap.

This product only fits Nukatap / Intertap taps.

This is a handy Intertap spout accessory that can be used for a large range of purposes, including attaching a counter pressure filler gun. This makes keg to keg transfers or cleaning out your beer lines easy.

Simply un-screw the regular nozzle and screw on the Liquid Ball Lock Post.

This product only fits Nukatap / Intertap taps.

Simply un-screw the regular nozzle and screw on the Stout Spout and use as you would a stout tap.

From: Kegland

NukaTap Flow Control Auto Close Spring.

The NukaTap Flow Control is the world's only forward sealing flow control tap that can use a auto close spring. By inserting the spring between the flow control device and NukaTap shuttle the tap will automatically close when you let go of the handle. This is perfect for customers who may not be diligent enough to remember to completely turn off the tap after each pour. Or for those with little kids or pesky cats that knock everything around!

This very inexpensive spring can save you from emptying an entire keg and then loosing a whole bottle of gas.

Note: The spring is not compatible with the NukaTap Standard Models, the auto close spring for those can be purchased here.

From: Kegland

This Nukatap mini & Nukatap FC spring is designed to suit all Nukatap Mini taps and also the Nukatap Flow Control (FC) tap. This custom made 304 grade spring size is designed specifically to ensure your Nukatap stays closed when it should.

Simple let go of the tap handle and the tap will snap shut and prevent accidentally leaving the tap on and emptying the keg onto the floor.

This handy, inexpensive devices suits all Nukatap Mini and Nukatap FC taps and shank combinations.

Note: Nukatap Mini sold separately.

From: Kegland

This duotight 8mm (5/16") adaptor is designed to suit the Nukatap Mini and will allow you to couple your Nukatap mini to a wide range of other 8mm(5/16") duotight fittings or be able to attach to the Duotight Flow Control Ball Lock Disconnect. This particular type of flow control ball lock disconnect includes a "tang" at the top of the push in fitting that couples with this adaptor. The combination of the two fittings prevents the tap spinning around while in use.

Other Parts Sold Separately

Ball Lock Beer Duotight Disconnect - Flow Control

From: Kegland

This bracket is used to mount a Nukatap Mini in either 6.35mm or 8mm to a table or bench. Ideal for impromptu gatherings in the park!

This bracket is compatible with tables that are up to 90mm thick. It can be adjusted to have the wing nut clamp in either direction, simply unscrew the flange piece from the threaded rod, then unscrew, then thread from the opposing side.

Please note: This item does not include the Mini NukaTap or Shank pieces. It is simply the stainless steel bracket.

From: Kegland

Most conventional beer taps are designed with a 10mm diameter nozzle/spout so you can pour pint in just over 10 seconds. This type of flow rate is great for high turnover bars and commercial venues but this high flow rate requirement is not not necessary or desirable for all applications. For compact portable systems, or for home brew draft systems, a slower flow rate is easier to control the flow and further reduces foaming issues due to the low liquid volume stored in the tap body.

This Nukatap mini is also more ideal for pouring smaller doses. For example cocktails where 150-250ml of liquid is dispensed is difficult to control with a high flow rate tap. For portable systems this tap and FC ball lock disconnect assembly is small enough to literally put in your pocket making it ideal for mini keg setups that you want to be portable or that you want to easily fit inside a domestic fridge where space is tight.

Forward Sealing

Forward sealing taps are absolutely the way to go when it comes to beer taps. The issue with rear sealing taps is that beer dries up on the tap piston. This is not sanitary and as more and more beer dries up in these components the tap can almost glue complete shut causing damaged seals or broken handles (this is particularly the case if it's left for some time to dry out with beer inside). These older legacy design still exist probably due to poor education. The forward sealing design do not have this problem and the tap drains out completely with no beer drying up on the mechanical moving parts in the same way. This makes the tap more sanitary and reduced maintenance. In may instances the price is similar so there is no reason to use a poorly designed rear sealing tap. All Nukatap taps are forward sealing.

Laminar Flow

Just like the Nuktap SS and Nukatap FC, the Nukatap Mini has been designed with laminar flow in mind. Laminar flow is critical for a beer tap as it means you will pour the beer with minimal foaming and a substantial reduction in wastage. Think about how many times a beer tap opens and closes in it's lifetime - 1000 or maybe 10,000 times? Laminar flow saves wasted beer in excessive foam and the better laminar flow easily pays for itself in a reduction in lost beer. Extensive modeling has been done on this Nukatap design to improve laminar flow.

Integrated Seals that are Indestructible and more Sanitary

Unlike other designs, the Nukatap Mini body is made from POK making it strong, robust and able to be autoclaved. The seals are also over-molded from Santoprene® making them hard wearing so they will literally last for the lifetime of the tap without the need for replacement. Santoprene® and POK both have excellent resistance to chemicals such as caustic soda, peroxide, phosphoric acid, lactic acid, citric acid, acetic acid, and all common chemicals sold and used in the beverage industry. The seals internally in are over-molded meaning NO fissures or cracks exist for bacteria, crud or yeast to hide.

Superior First Pour Foam Due to Low Thermal Mass and Conductivity

First pour foam is an issue caused by a warm tap body. For most taps to pour well it's important to dispense enough beer to cool the tap body down before the tap will pour well. In addition to this the conductivity of the tab body also makes this worse so insulative materials simply work better than conductive materials. The Nukatap mini not only has very low thermal mass but is also highly insulative being made mostly from Santoprene and POK. The combination of these two factors in conjunction with superior laminar flow makes for the lowest "first pour foam" effect out of any tap ever produced.

Long Shank Alternative (Sold separately in Duotight design)

Most conventional beer taps require a large 22mm hole to be drilled through the wall of your keezer/cooler/wall. Traditional long shanks also generally have a large volume of liquid that sits inside the wall unrefrigerated which is not ideal. This new long shank alternative is designed to suit any wall thickness and greatly reduces the stagnant beer sitting in the shank itself. For walls up to 80mm thick we have provided three screws however if the wall is thicker you can also use 6 small wood screws or something similar and attach three screws from the front and 3 from the back allowing you to go into any wall type.

Another advantage of this new design is the tap will never accidentally rotate. Typically other long shank beer taps rely on the hex nut on the shank to be done up tight enough to prevent rotation but if the wall compresses (often the case with foam walls) the tap is allowed to rotate. This new design has three fixing points making it impossible for the tap to rotate accidentally as the interlocking teeth behind the collet allow you to set the angle and then do up the collet to fix the tap permanently in that position.

Other Accessories (Sold Separately)

Nukatap Mini - Wall Mount Shank Kit - duotight 8mm (5/16")

Nukatap Mini - Self Closing Tap Spring

Nukatap Mini - duotight adaptor - 8mm (5/16")

Flow Control Ball Lock Disconnect

This bracket is used to mount a Nukatap Mini in either 6.35mm or 8mm to a cooler/esky/chilly bin or your home refrigerator or bar fridge. No need to drill any holes!

This bracket is compatible with walls/fridges that are up to 90mm thick. It can be adjusted to have the wing nut clamp in either direction, simply unscrew the flange piece from the threaded rod, then unscrew, then thread from the opposing side.

Please note: This item does not include the Mini NukaTap or Shank pieces. It is simply the stainless steel bracket.

From: Kegland